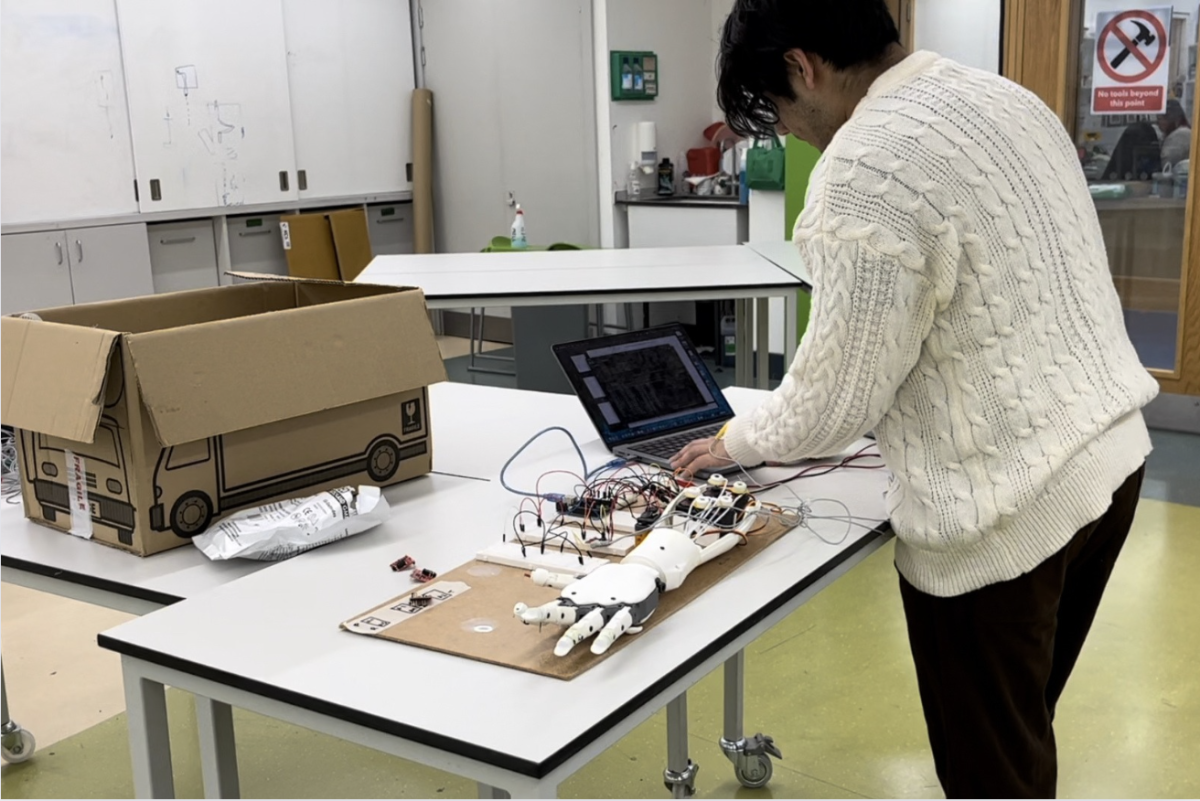

Prithvi Srivastava (’24) began designing a prosthetic hand in his Advanced Design Thinking Apprenticeship class at the beginning of the 2023-24 school year. Srivastava became interested in creating the hand after his passion for biomedical engineering led him to research prosthetic limbs. Srivastava strives to continue prototyping and creating multiple designs until it is usable by amputees.

Although Srivastava has faced many challenges while creating the hand, he said he believes this is a great project to pursue.

“It’s my first hands-on project,” Srivastava said. “So, obviously, there are a lot of difficulties with it, and I’m slowly getting better and better and I think I’ll be able to apply [these skills] in college.”

Although creating the prosthetic involved several mechanical systems that Srivastava wasn’t familiar with, he said the project was doable at his level and provided a good learning experience.

“It actually wasn’t that difficult,” Srivastava said. “Just some basic Arduino that I learned and then applied, that’s all it really took.”

After Srivastava decided he wanted to take on the project, he said he emailed professors to get their expert opinions and advice.

“[My teachers] gave me like a green light and said it’s not something that’s that hard to do,” Srivastava said. “I built the first model really quickly, but the second model takes a lot more time because it’s a lot more effort and a lot more complexity.”

Prosthesis Terms by raj_chamria

In order to build the prosthetic, Srivastava said he gathered materials from the MILL but additionally ordered items online that were not available at the school.

“ASL has their own 3D printer, and I just use one of their plastics,” Srivastava said. “The MILL does have a lot of resources, including screws, screwdrivers and everything you need really to actually make [the prosthetic hand].”

Although Srivastava’s design already includes t many complex parts that require careful planning, he said he hopes to integrate wireless electromyography in future iterations to make the hand usable for amputees.

“For a more complex design, it’s gonna take a lot more time to understand how I can make as much space as possible to account for wiring and to account for the size of the servos and other factors,” Srivastava said. “The base design is good, but it needs to be improved on, especially for the wrist movement.”

Due to the amount of excess wiring attached to the hand, Srivastava said it is currently unusable. However, with the addition of more advanced technology, Srivastava said the hand will improve in practicality.

“You can see from the design that it’s not actually something that’s wearable for someone,” Srivastava said. “The way you make this more portable, the way you make this an actual prosthetic, is by reducing the amount of wiring and making it wireless and taking Bluetooth into account.”

Srivastava said he aims to make future hands as affordable as possible to spread his reach to many people.

“The Hero Arm, which is obviously the most advanced tech on the market, costs around 8,000 pounds for the full design”, Srivastava said. “Essentially, I want to try and minimize that as low as possible and my hope would be to make it around 1,000 pounds.”

Srivastava’s hand achieves hypothetical affordability because many of its mechanisms are created with 3D technology. Srivastava said other companies create their hands through injection molding, a process that is much more costly.

“We’re using 3D printing instead of metal and other sorts of expensive materials,” Srivastava said. “Using 3D printing, which is just plastic, decreases the cost a lot, and the technology required for the wiring or the batteries and everything like that is not that expensive.”

Srivastava said completing this project will help him build expertise in topics related to biomedical engineering.

“Doing this project will not only improve my knowledge of coding, but it will also help me build an understanding of how artificial intelligence can actually be used in the field of biomedical engineering,” Srivastava said.

Moreover, Srivastava said prosthetic limbs mainly focus on the anatomical aspect of biomedical engineering, and in the future, he aims to integrate AI into his creations.

“I would want to apply probably more artificial intelligence into recognising patterns of diseases,” Srivastava said. “Something my brother showed me just recently, which he also did in his research, was that he was using AI to track eczema patterns from the brain.”

Dedicating time to crafting the prosthetic limb is something that Srivastava said he enjoys and wants to improve his skills as much as possible. He said he hopes his dedication will allow him to develop many different items to help amputees and others with medical problems and disabilities.

“The thing about this field is that it’s very limited to a certain population, obviously amputees,” Srivastava said. “Being able to help even like a small part of that society, that’s sort of the goal.”